Business

BUSINESS

> Business >

> Business >

Silicon Anode material

Silicon Anode material

The anode is one of the four core elements of a lithium ion battery

and determines the battery’s storage volume and operating voltage.

Graphite is widely used as an anode material and has the property of

low capacity per unit volume

resulting in the limitation of

volume (about 370mAh/g) for graphite based anode materials.

To overcome this, a next-generation anode material is required.

FIC Advanced Materials

has improved the property of graphite by utilizing a spherical graphite

assembly technology that enhances the capacity, power, and cycle

characteristics compared to ordinary spherical graphite. Moreover,

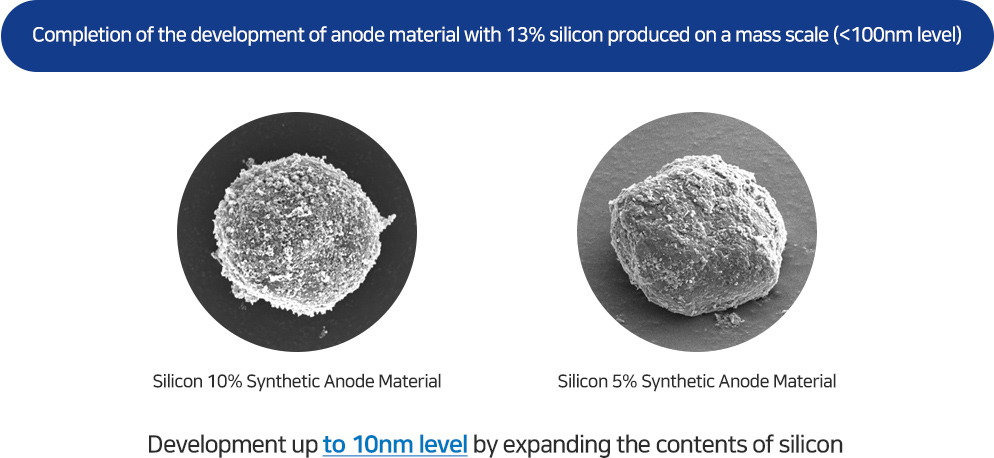

the company succeeded in the mass production

of silicon anode material that extended the battery capacity significantly

by adding silicon and prevented structural damage during cycles.

FIC, competitiveness in the silicon anode market

dominate silicon anode material market with technology and competitiveness leading the era of the second generation battery

1Silicon nanotechnology: mass production of < 100nm level nano silicon

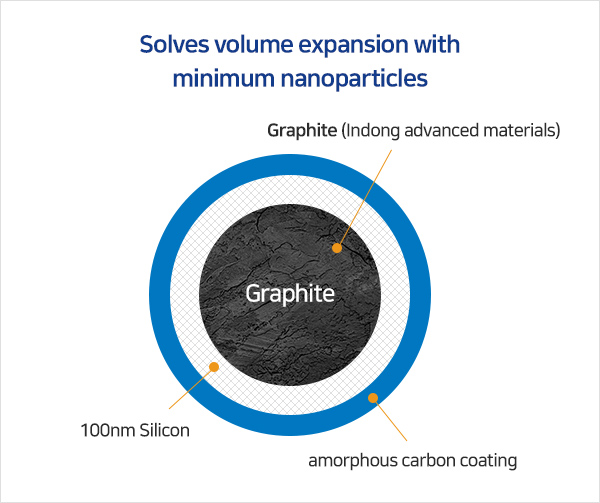

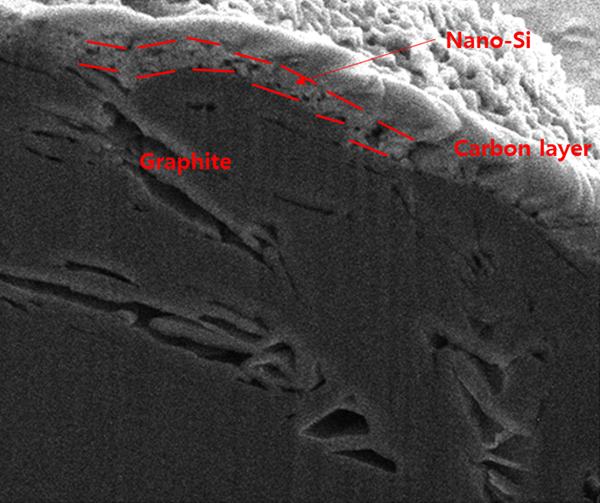

2 Deposition and coating technologies

- Enhance battery capacity while minimize silicon volume expansion

3 Spherical assembly technology

- Graphite assembly technology to achieve excellent efficiency and rapid charging and discharging properties

4 Low cost

- Unique technology to recycle end-of-life solar panels and extract pure silicon

5 Vertical integration

- Integrate value chain of battery industry from raw materials (Indong Advanced Materials, Inc.) up to the final goods (Eurocell, Inc.)

“FIC preoccupied the silicon anode materials market with technology and competitiveness that leading the era of 2nd generation batteries (silicon anode materials)"